The Energy Cure Production Platform

Traditional battery manufacturing methods face mounting environmental and economic challenges. With our groundbreaking Raicure™ technology, Ateios tackles the limitations of traditional thermal curing, unlocking a new era of efficiency, sustainability, and performance in battery manufacturing.

Watch Video Overview

The Problem

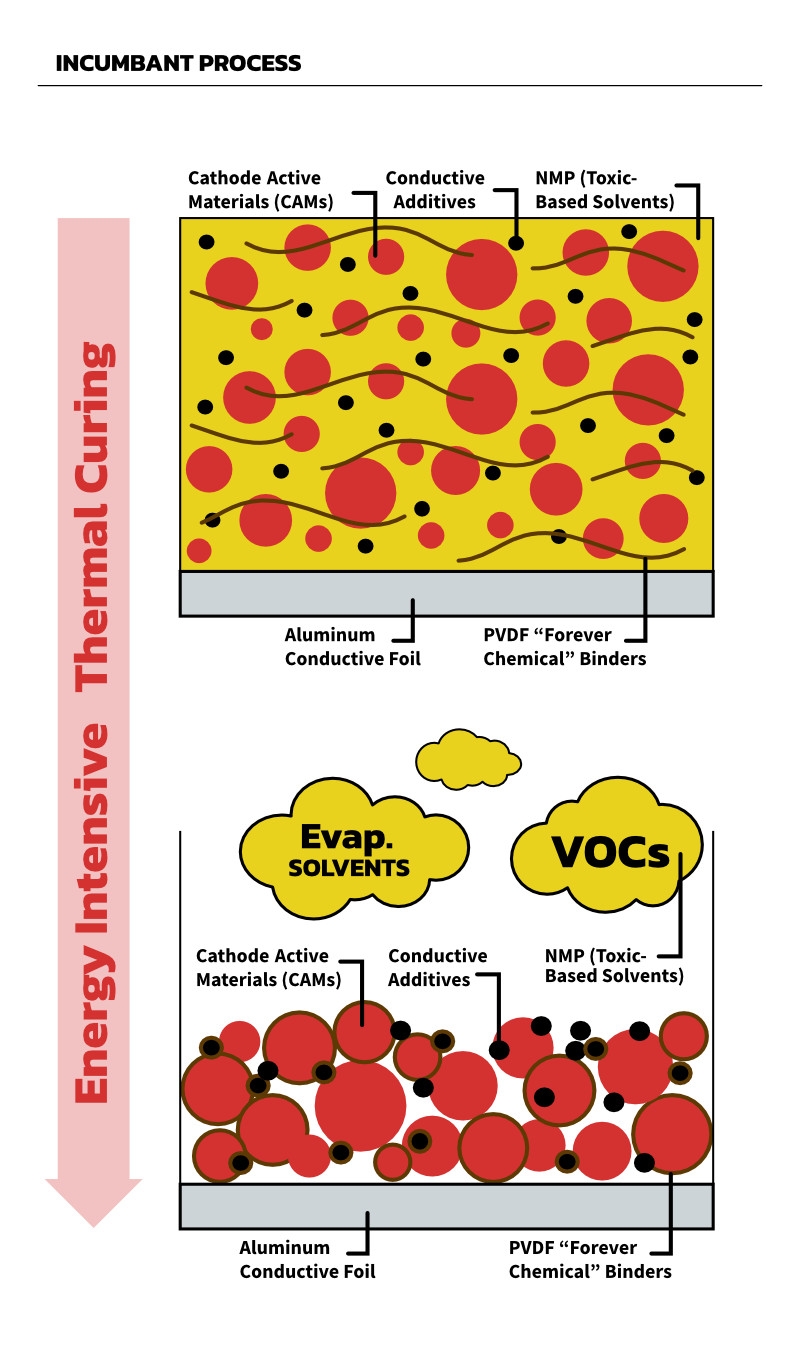

Traditional battery manufacturing relies on energy intensive and inefficient thermal curing of electrodes.

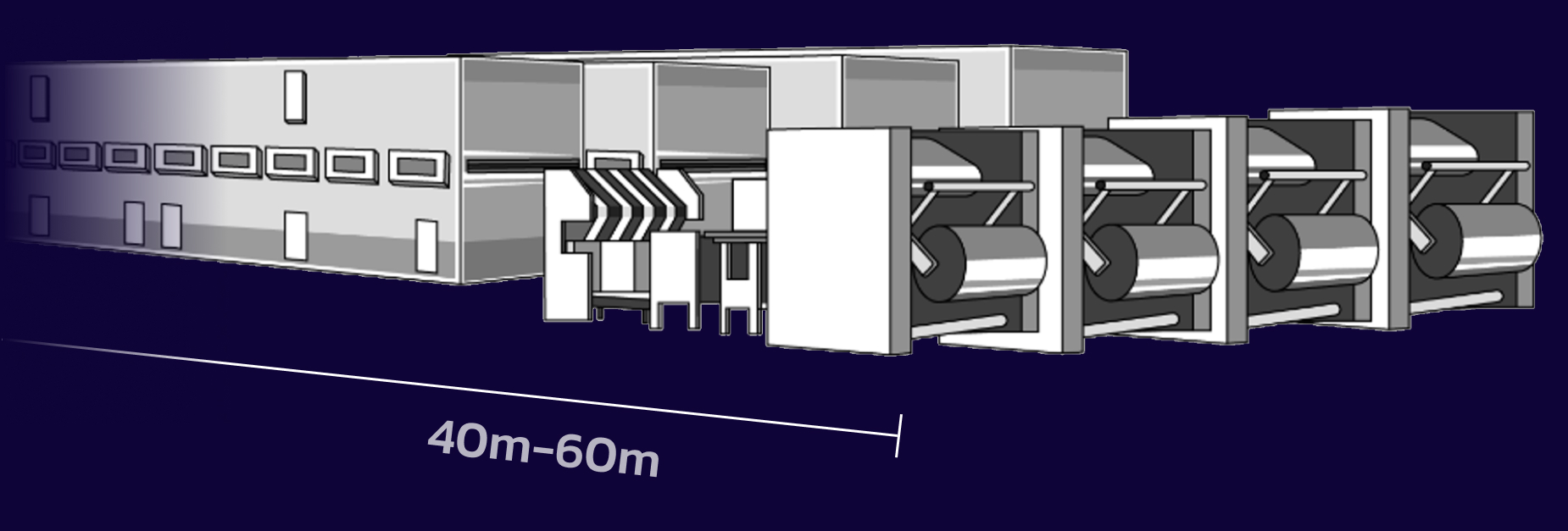

High Costs: Due to using expensive, toxic solvents ($5/L) and the energy ($8M in natural gas/year/line) to remove them.

Lower Yields:

Poor adhesion causes failure from the assembly process.

Limited Energy Densities: Difficult to coat over 100 microns due to poor mixing of high molecular weight polymers.

Environmental Concerns: 95% of batteries use polymers categorized as PFAs or forever chemicals and and use of toxic solvents generates ~93 lbs CO2/kWh.

The Solution

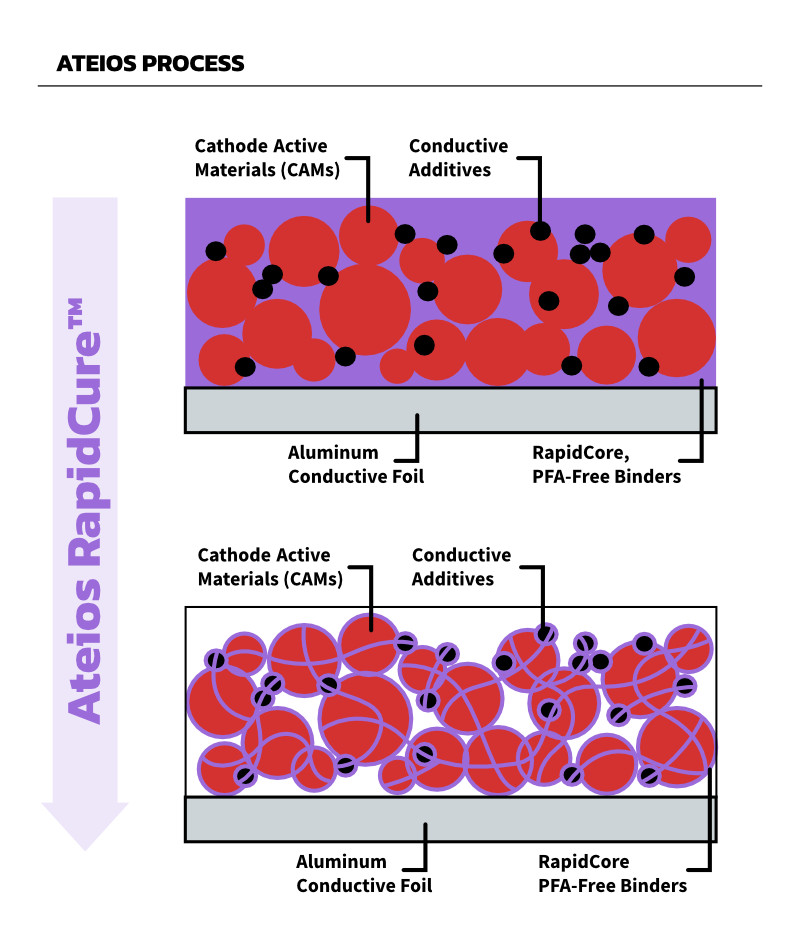

Ateios Systems’ revolutionary RaiCure™ Technology, in collaboration with Oak Ridge National Lab, replaces heat curing with energy-curable polymers that improve the energy density, cost, yields, and environment for all types and sizes of batteries.

Developed in Partnership With

20%

Cost Reduction

Eliminating the solvents, >$20M CAPEX, and $8M in annual OPEX costs

50%

Increased Energy Density

High-quality films over 200 microns

2x

Yield Quality

Improved adhesion compared to incumbent polymers

~0

Environmental Impact

Completely free of forever chemicals and energy consumption reduced by 82% to (17 lbs CO2/kWh)

The Science of Radiation-Based Electrode Curing

Ateios’ breakthrough is streamlining the manufacturing process, rather than creating whole new battery chemistry, they can adapt their platform quickly for a wide range of existing applications. Their technology especially shines in small electronics applications that have been waiting for an innovation like this.

- Krisztina Holly, Good Growth Capital

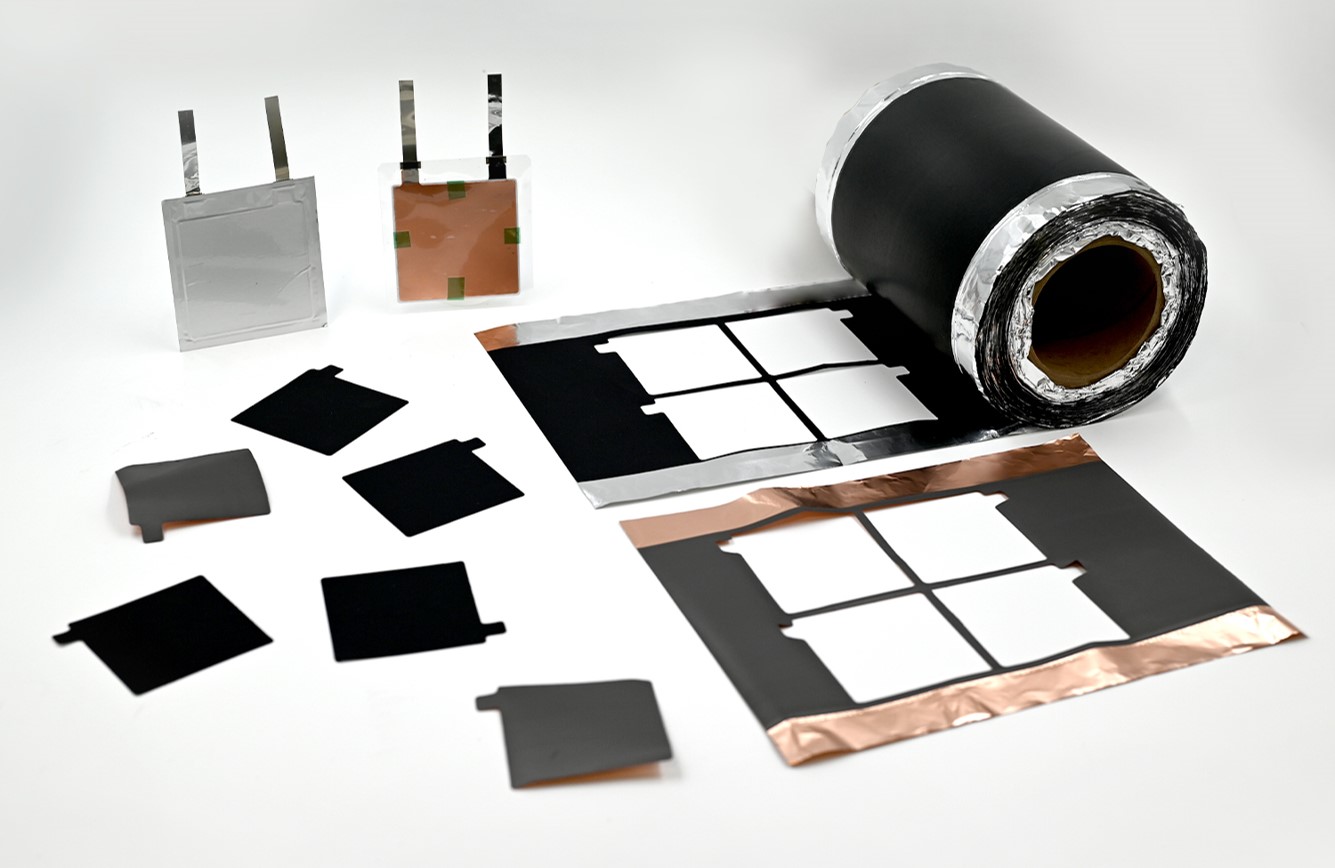

Test an Ateios Electrode Today

Answer a few short questions to get a sample electrode or battery and estimates for production.

Start